Our passion and our commitment,

for over 60 years, in sheet metal stamping and dies manufacturing.

Osa S.p.a.

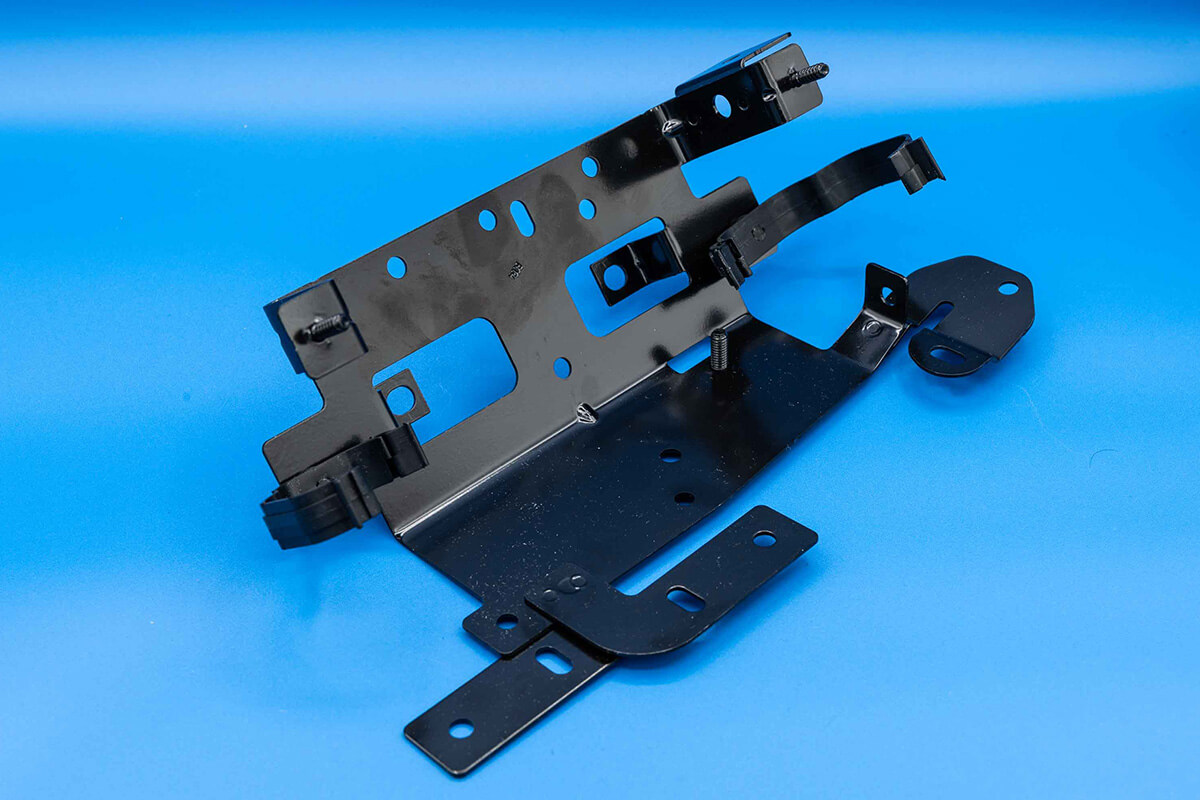

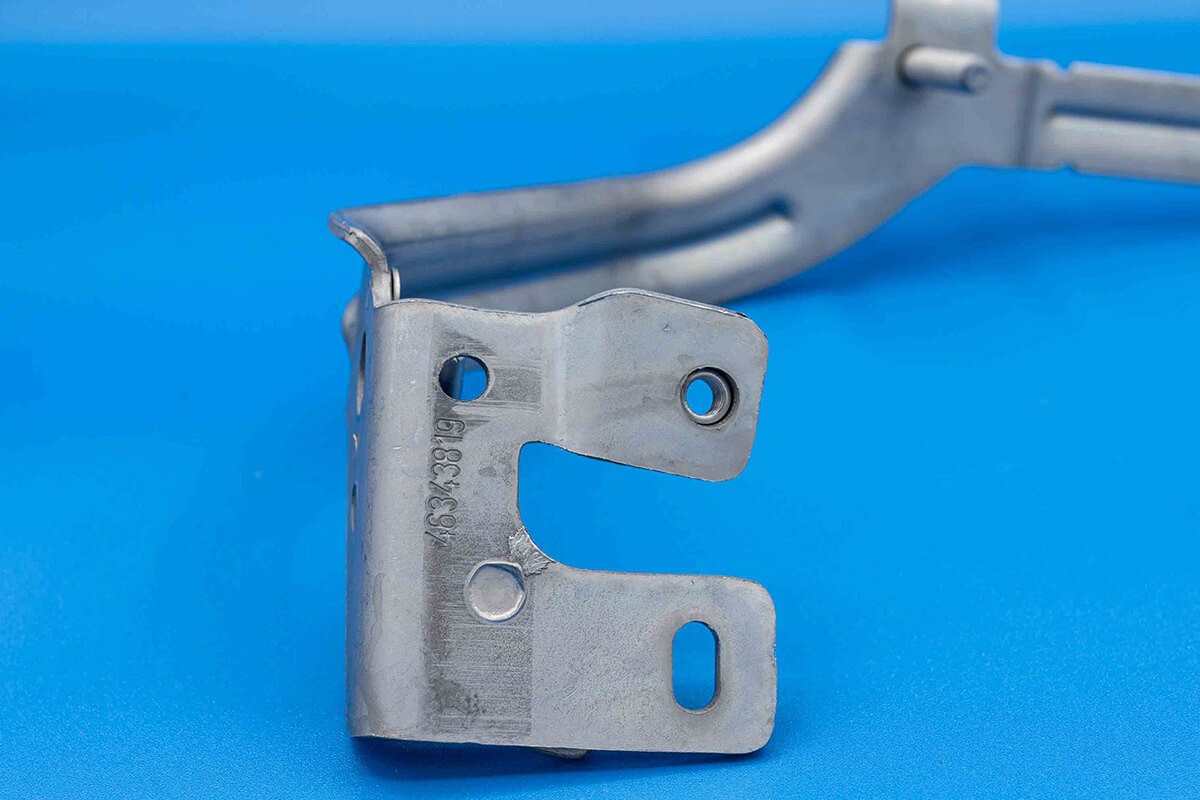

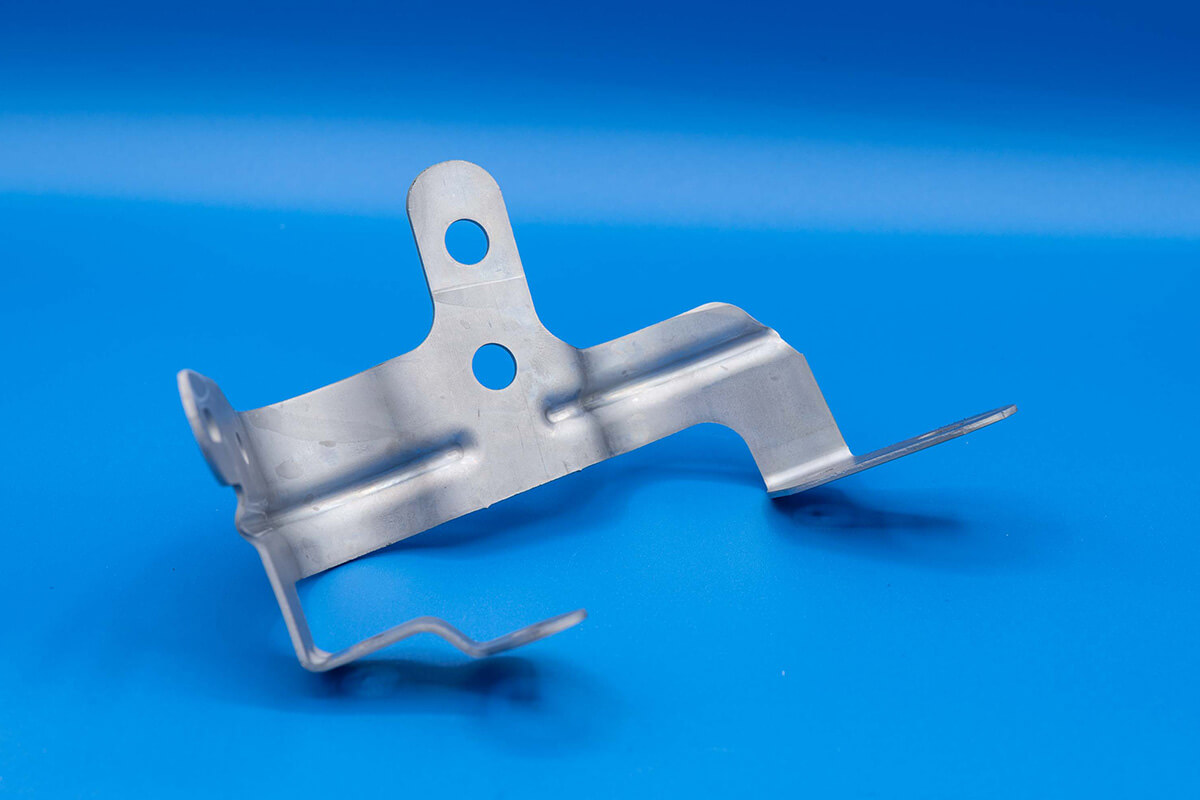

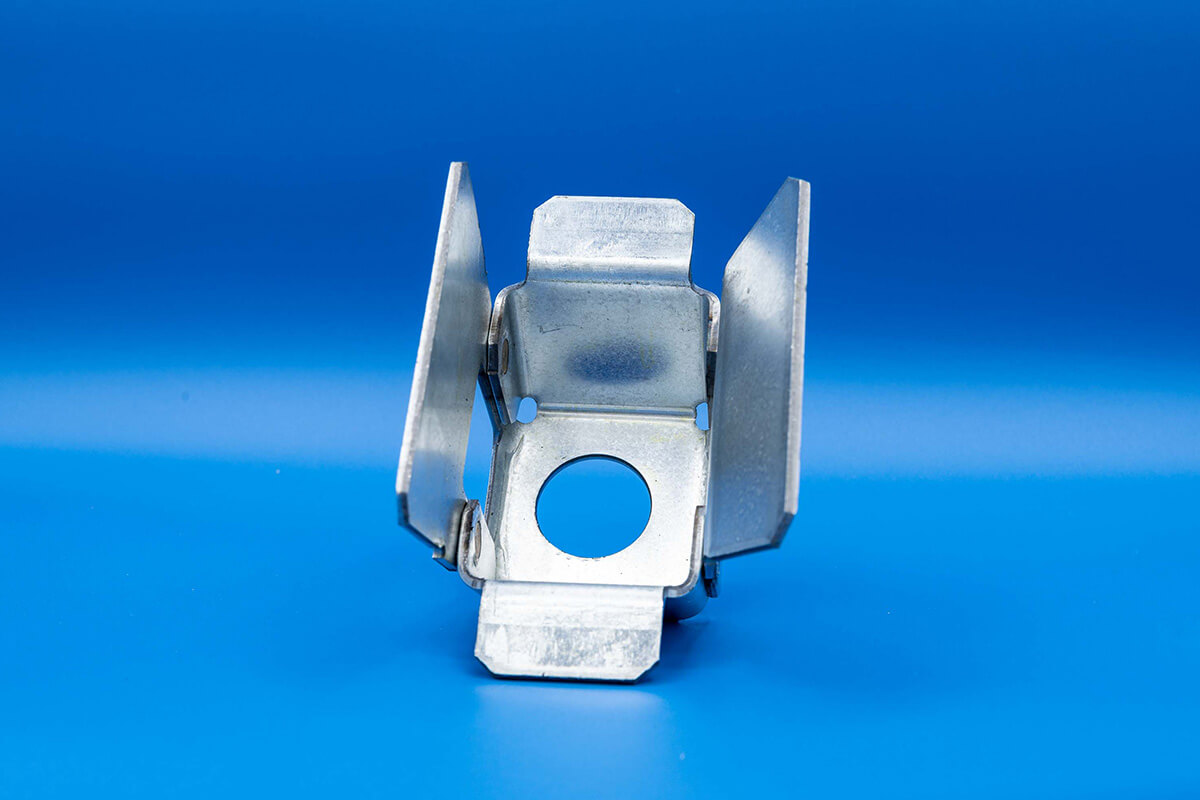

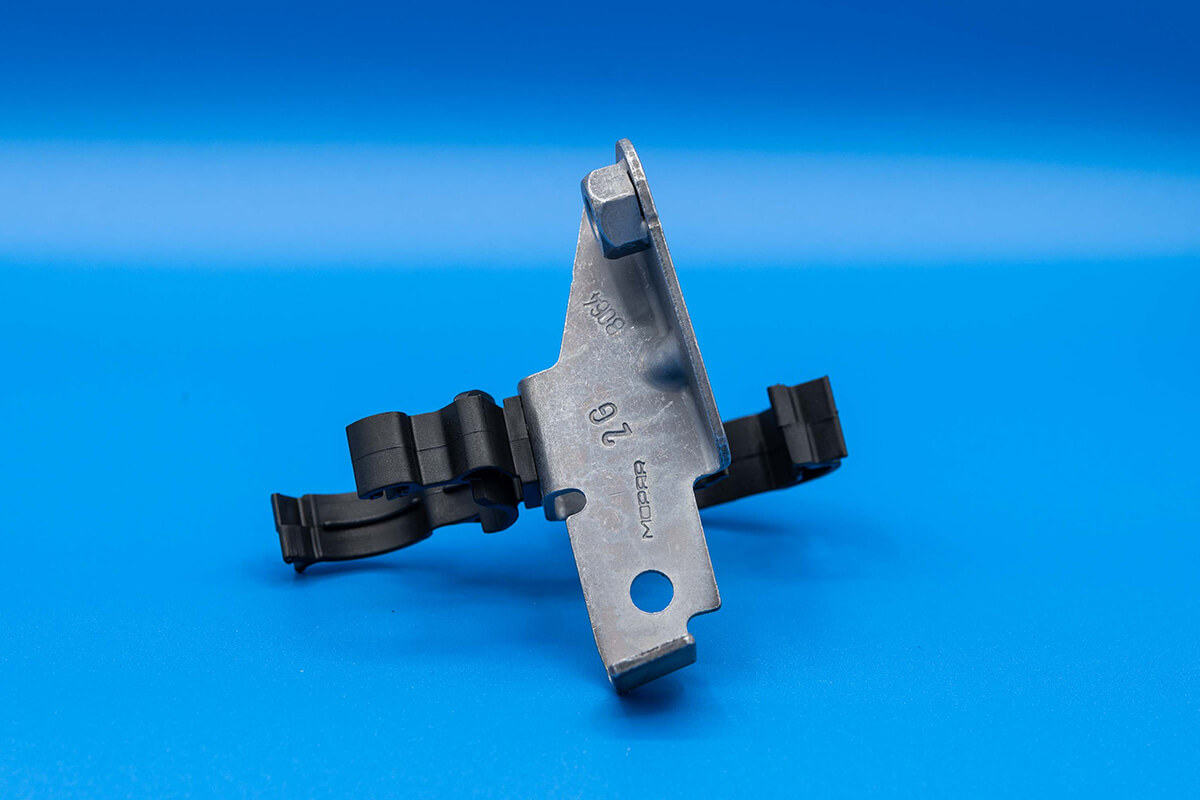

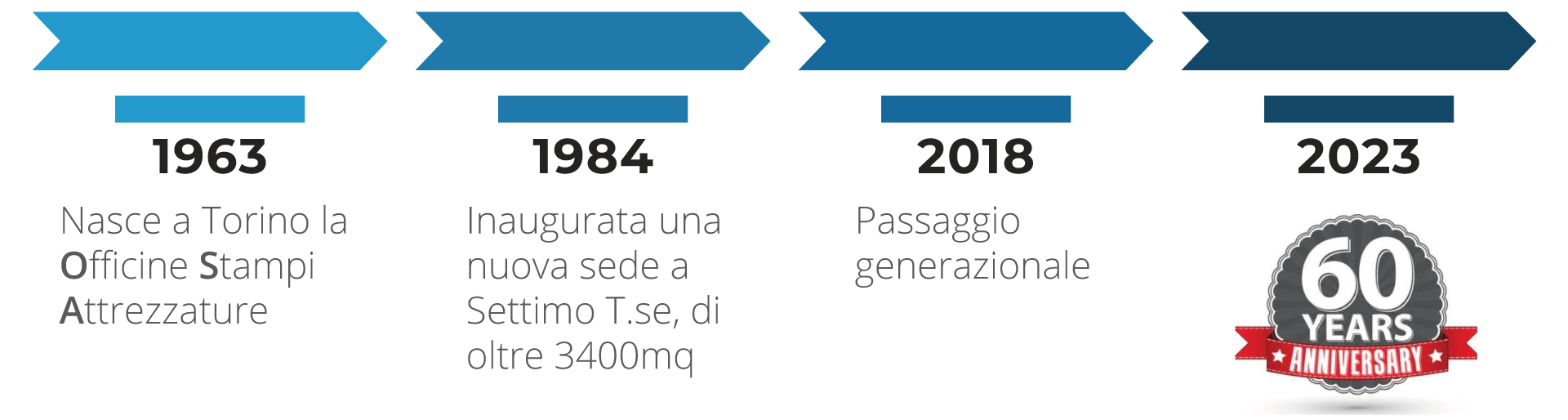

Osa is an Italian company based in Settimo Torinese. It produces metal components for the automotive sector. Its main activities include moulding, assembly and welding.

Osa S.p.a. has over 60 years’ experience in the high-quality metal manufacturing sector, specialising in cold sheet metal stamping, assembly and welding. This decades of experience makes it the ideal partner for industries in this sector, which have always demanded high quality standards from their suppliers.

Our

solutions

Thanks to over 60 years of experience in the engineering field our experienced team can guarantee:

WHY YOU SHOULD

CHOOSE US?

WHY YOU SHOULD

CHOOSE US?

CERTIFICATION

CERTIFICATION

CERTIFICATION

Osa S.p.a. offers itself to customers as a reliable and attentive partner in terms of quality standards, equipped with a certified company Quality System that complies with IATF 16949. The attention we have always paid to environmental issues is guaranteed by ISO 14001:2015 certification. The company has also embarked on a path to increasingly increase sustainability issues internally.

our

customers